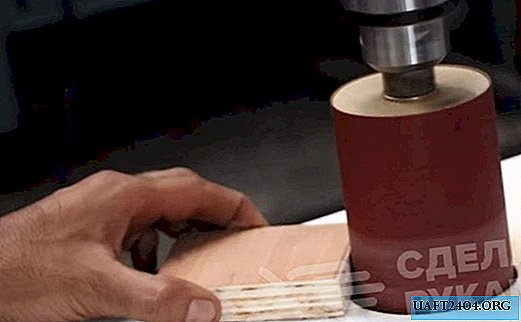

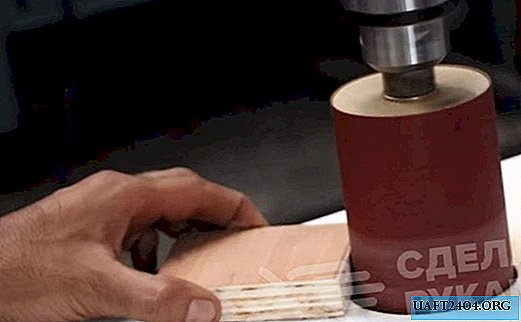

This homemade product will be useful to everyone involved in the processing of wooden blanks. Simplicity and functionality, as well as low cost are the main advantages of such a device. Moreover, the drum can be used not only vertically, but also horizontally. Universal thing, in a word.

Manufacturing process

Using an electric drill with a crown, five round blanks of the same diameter must be cut out of a plywood sheet, in the center of which then a through hole must be drilled.

After this, the wooden workpieces must be mounted on a bolt of suitable diameter and length, lubricating each “layer” with carpentry, or even better, with some kind of universal multi-component adhesive. Then the whole thing must be tightened with a nut.

After the glue dries, the surface of the drum must be sanded so that it is even and smooth. Further, over the entire height of the workpiece, a shallow longitudinal cut must be made with a circular saw or a conventional hacksaw.

The final stage of work

After the wooden drum is ready, it remains only to cut out a suitable strip of sandpaper in size, wrap it around, and put the edges into the previously made cut. To securely fix the tape in the drum, it is enough to tighten one self-tapping screw on the side. That, in fact, is all.

With the help of a shank, in which the part of the bolt acts, the drum is simply inserted into the chuck of a stationary vertical drill and is ready to work. So that he does not hang out during the grinding process, you will have to make a special wooden platform. See all the details in the video on our website.