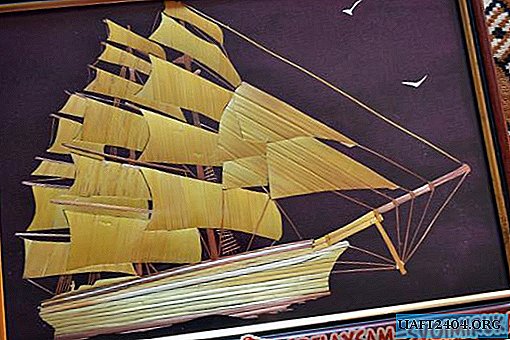

Using this device with a vertical screw clamp made of metal scraps, it is possible to reliably fix pipes and round billets of different diameters for the purpose of their subsequent machining with a grinder and a file, as well as for threading with a die.

Such a home-made device compares favorably with a conventional vice, which is not able to provide a complete clamp for rolled pipe, steel bars and other round billets.

Thanks to the special design of the clamping jaws of a vertical vise, it is much easier and more convenient to process pipes and other cylindrical parts: cut with a grinder and drill holes at different angles. The design of the device itself is very simple - a base of sheet metal, a vertical stand, fixed jaws at the bottom of the vice and a clamping screw with a sponge.

The main stages of work

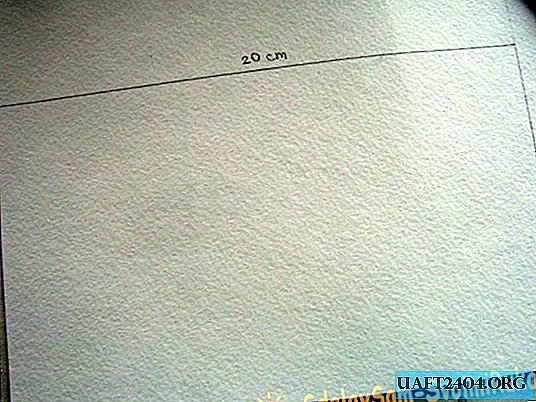

One of the main elements of the device for fixing round pipes is a screw with a handle, which can be removed from a conventional old vice or made independently from a steel bar of suitable diameter. Then we make the base - from a piece of metal 30-40 mm thick. At the edges we drill holes for attaching to the desktop.

Next, you need to weld a vertical stand from a metal plate with a width of about 50-60 mm to the base - it should be located at right angles. A threaded guide for the pressure screw is welded to the rack itself.

The lower clamping jaws are made of two pieces of a thick plate 10 cm long, and on the surface you need to make longitudinal notches with a grinder. They are welded to the base at an angle. The third sponge must be welded to the steel sleeve, in which the hole for the fixing bolt is drilled. Notches are made on it, not only along, but also across.

Then all the construction details must be cleaned with a grinding disc, painted and assembled. The result is a home-made vertical vise for fixing round pipes and cylindrical workpieces.