Many have noticed how the mechanism for opening / closing doors on a bus is very convenient and compact. Having some experience and a minimum of tools, you can make the same doors in the wardrobe with your own hands.

The main material is a rectangular profile pipe 40 * 20 mm. Also required are metal strips, a profile of a different size, bolts with nuts and a laminate for sheathing the cabinet doors.

The main stages of door manufacturing by bus technology

The first step is to cut the profile pipe with a grinder into pieces of the right size. Then the frame of future doors is welded from a pipe of a larger cross section.

After this, you need to make the sliding parts in the same way, and then weld strips to them to fasten the facing material.

When the frames are ready, it is necessary to make rotary mechanisms. Then you need to assemble the entire metal structure, check its performance and paint it in the desired color.

Finishing touch

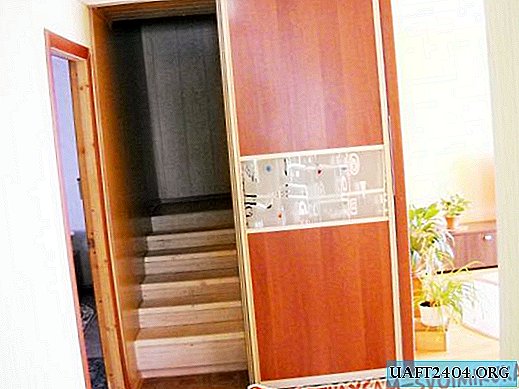

The last operation will be the installation of decorative panels (you can also use pieces of laminate) and the installation of doors directly in the wardrobe.

The design is lightweight and compact. Such doors are perfect for those rooms where there is not enough space for opening swing type doors, and the original appearance will successfully complement the interior of the hallway or bedroom.

For the manufacture of such doors you will need not so much material, but the work can take more than one day.

For details on how to make original home-made doors for a wardrobe with your own hands using bus technology, see the video on the website.