In this review, the author shows the manufacturing process of a multi-grinding machine for a home workshop.

A home-made grinding machine combines the functions of a grinder and drum grinding.

In this multi-grinding machine, at the same time, sanding belt of various grain sizes can be used for processing workpieces.

For the manufacture of a grinding machine, the master uses an affordable and relatively inexpensive material - plywood.

The main stages of work

The first step is to cut off a piece of plywood that will be used as a base. Then we cut off two more pieces of plywood - we fasten them to the base on the loops.

Next, you need to cut four wooden bars. In them, the author drills holes in which it is necessary to press in the bearings.

From a wooden bar it is necessary to make a round, which the author cuts into blanks of the desired length. In the center, drill holes.

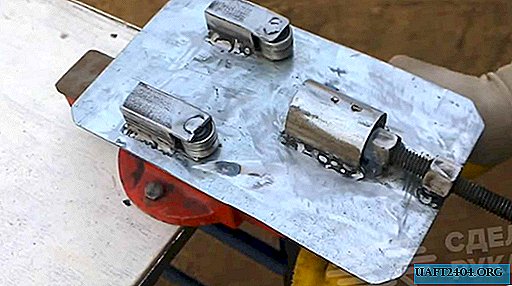

The resulting rollers (for the sanding belt) are put on a round metal bar, which we thread through the holes in the bearings. Set the bars on plywood (base).

The author fastens a piece of plywood to two bars - two fastenings for the upper rollers fasten to it.

As a drive, you can use an electric motor with a power of 350-750 W. We connect the motor shaft to the shaft on which the lower rollers are located, using the adapter sleeve.

At the last stage, we wind the grinding paper onto the rollers of drum grinding. The homemade product is ready - you can get to work.

For details on how to make a 2-in-1 multi-grinding machine with your own hands, see the video.