Repairing a bicycle (child or adult), as well as car service, requires a specially designated place. Speaking specifically about bicycles, they are usually repaired the old fashioned way - turning the top upside down. But it will be much more convenient to carry out repair work on an inclined metal rack, which you can make yourself.

Preparatory work

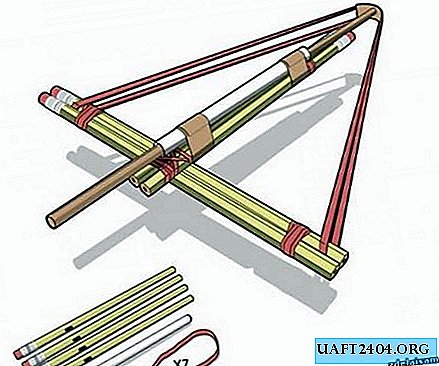

For the manufacture of this device, the following materials will be required: a profile pipe, a round steel bar, two thin plates, a piece of sheet metal, a semicircular clamp with nuts and a telescopic tube with holes.

First of all, you need to weld two pieces of a square pipe perpendicularly (strictly at an angle of 90 degrees) to get a T-shaped part. To set the right angle correctly, use the magnetic corner - a very convenient thing. In the same way, you need to weld a section of a profile pipe and a steel bar.

After that, using electric welding, it is necessary to rigidly connect T-shaped parts to each other, and the one with the bar should fulfill the function of a supporting element of the whole structure. For additional rigidity, a steel plate (also at an angle) must be welded to the profile pipe and round timber.

The final touch - and you're done!

A telescopic tube must be welded to the top of the structure at an angle of 70-80 degrees. From the outside, where the jib from the plate is welded, you need to weld another piece of sheet metal. It is necessary to weld two pieces of the corner with an edge to the telescopic tube (in the extended position).

The device for the bike device is ready. Using such an inclined rack to carry out various repairs will be much more convenient. See the video for a step-by-step process of assembling a metal structure and its application in practice.