If you want to surprise your friends, make an exclusive cigarette case made of copper and brass with your own hands, which can rightly be called a small masterpiece made in a home workshop. The work will be painstaking and jewelry, and may take some time, however, the final result is definitely worth all the effort spent on making a cigarette case.

Body manufacture

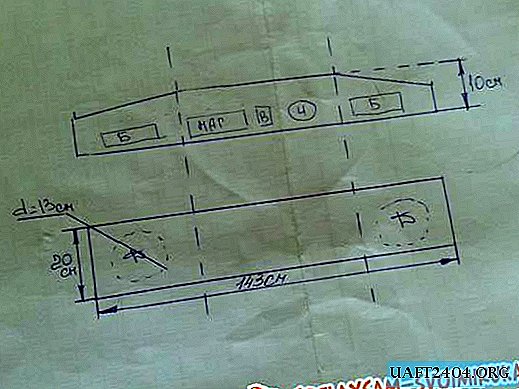

First, with the help of a caliper, make markings on a piece of sheet of copper, then we take scissors for metal in our hands and cut a rectangular plate. Next, you need to put three brass tubes of the same size (close to each other) on a flat surface and connect them using a special solder for soldering non-ferrous metals, molten using a gas burner.

Then we lay the “paired” brass tubes on a copper plate and bend on both sides so that the connecting seam is in the middle. We take out the tubes, and on the inside of the case we apply a narrow strip of copper, and on the sides - solder, after which we heat it with a gas burner. As a result, we get a beautiful and neat seam.

Cigarette case decoration

We attach to the body a piece of paper with marks for the holes and core the surface of the copper plate. For this purpose, it is best to use a spring core so as not to deform the body with hammer blows. Further, without removing the paper template from the surface, we drill holes using an electric drill or drill.

We insert copper wires into the obtained holes, imitating the seam with threads, and melt with solder. The surface from the inside of the case is treated with a grinding nozzle - to remove irregularities. The bottom of the case is made of a brass strip of brass, which must first be soldered, and then cut and grind the file along the contour.

At the last stage of work, we make decorative elements from brass, which are fastened by soldering, and a cover for a cigarette case. See the manufacturing process in the video on the site.