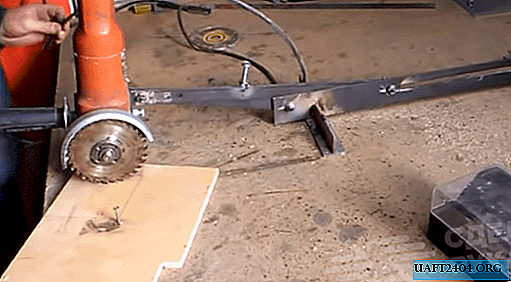

From an old small vice you can make a useful multifunctional tool for the home workshop. First of all, we cut off the excess parts with the grinder and carry out a small restoration - we clean the surface, after which we paint with spray paint.

While the vice is drying, you can begin to manufacture the second part of the homemade product. To do this, cut off from the steel corner 50x50 mm three identical pieces with a width of 4 cm. We clean the parts with a grinder, then weld two corners together. Previously, in all corners you need to drill one hole.

Making a transition pad

To make the transition pad, you will need a piece of metal strip 5 cm long and 10 mm thick. Then we drill holes in the center and edges, after which we cut the thread. Next, a piece of bolt or stud M8 is screwed into the central hole in the transition pad.

Another segment of the bolt is twisted into the hole in one of the corners. Please note that the threaded part of the segment of the bolt (or stud), twisted into the transition area, should not be twisted out of its landing "socket", so it must be welded.

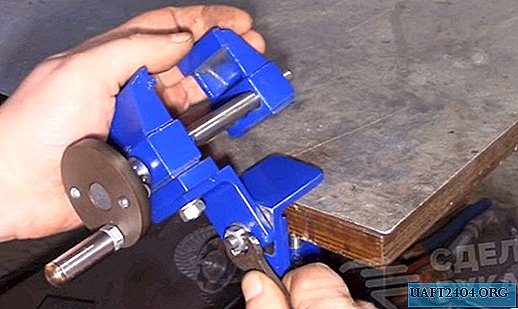

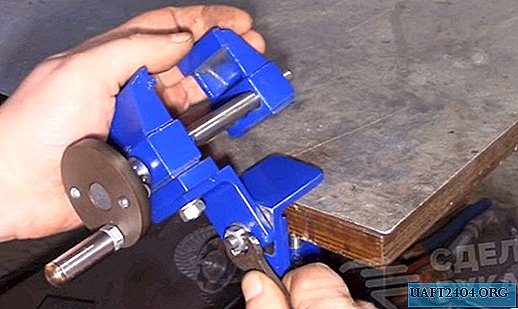

Using four screws, we attach the adapter pad to the vise (the screw caps must be recessed into the plate) with the corners, we additionally fix the flywheel, and the self-made device is ready for operation. The result is a compact swivel vise with tilt.