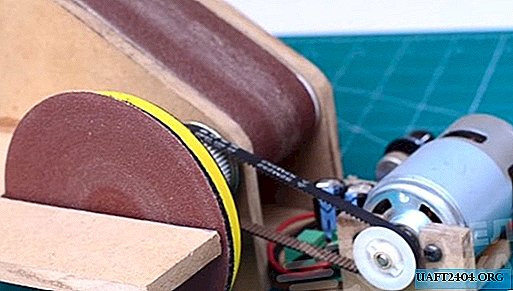

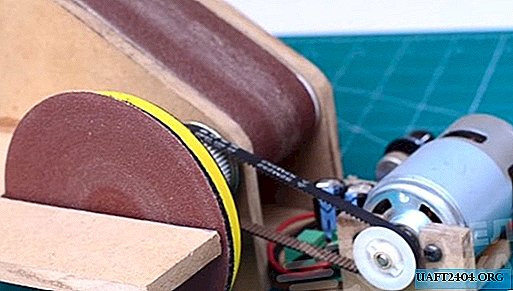

This home-made disk and belt sander is equipped with a DC motor with a torque of 0.2 Nm. The design is made using MDF sheets. It is also possible to adjust the engine speed through the use of a control unit.

The universal 2 in 1 grinding machine has a compact size, so it is ideal for use in the home workshop, in the country or in the garage. Read more about how to make such a machine with your own hands, read on.

The main stages of work

From a sheet of MDF (you can replace plywood with a thickness of 8-10 mm) we cut out blanks of a certain shape, which we fasten together with glue and screws. This will be the basis for the sanding belt. We make rollers from pieces of plastic pipes and bearings, which must be secured with a stud with nuts.

The third roller, which will be located in the lower part of the base, is made of a large diameter tube - we insert round "plugs" cut from MDF into the end holes. Then we drill holes in them for a bolt with a diameter of 12 mm and install in bearings.

Assembly assembly

Next, from a piece of MDF, we make a seat under an electric motor, which we fasten to two screws. On the M12 bolt in the lower part of the base and the motor shaft we put on plastic gear pulleys for the belt. On the free end of the bolt we attach the nozzle under the grinding disk.

At the last stage of work, we make work tables for a grinding disk and belt grinding, and also install a control board for adjusting engine speed (the board itself can be ordered on the Internet or done independently if you have the skills to work with radio components and soldering microcircuits).

We connect the power adapter and the universal grinding machine is ready to work. For a detailed assembly process of this design, see this video.