The obvious advantages of a home-made sharpening device are: compactness, ease of use, as well as simplicity of design and low cost of the materials used. The budget option for knife sharpeners is the best solution for home and garden.

Since the main criterion for the manufacture of this home-made sharpening device is the affordable cost and simplicity of design, we will use wood as the main material. You can also use plywood with a thickness of 16-20 mm.

The main stages of work

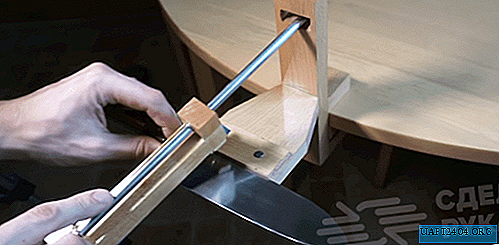

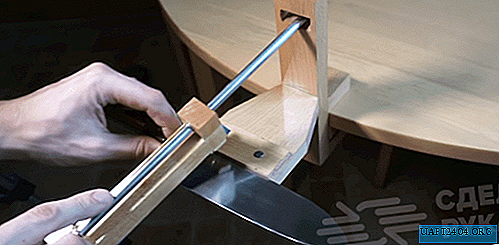

First of all, we cut the blanks of the desired size. Then in a vertical rack (in the upper part) we make a “window” of a rectangular shape. In the lower part of the bar and in the middle we drill two holes into which we install dowels. Then we fix two square-shaped blanks.

Next, we take a rectangular plank and on the circular saw or with the help of a jigsaw we cut off the upper corners. Then, at the end of the workpiece, we drill two holes - this operation is best performed on a drilling machine. You will also need to drill a few holes in the plank itself.

At the next stage, we connect two parts with each other using self-tapping screws. Additionally, you can coat the joint with carpentry glue. Then it remains only to focus on fixing the sharpener to the table and the pressure bar. We clean the finished product with sandpaper and cover with varnish or mineral oil.

The final touch is the manufacture of the whetstone itself. It is a wooden part that is mounted on a steel round rod. For sharpening knives using ordinary sandpaper. The detailed process of manufacturing a budget knife sharpener, see the video on the site.