A simple home-made rivet for rivets can be made from improvised materials. This is especially true in cases where you need to put just a few rivets, but there is nothing suitable at hand. Do not buy factory riveters for a single use.

Many will say that it is much easier to buy a disposable Chinese instrument for 100-200 rubles. No one argues, which is easier. But sometimes there are situations when you need it here and now, so this option of a rivet made in haste can be useful to someone.

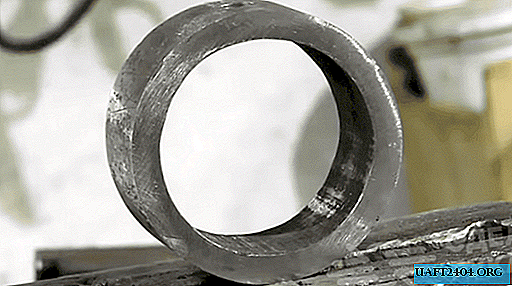

The first step is to cut a piece of thick-walled pipe with a diameter of 57 mm and a length of 3.5 cm. In the resulting workpiece, it will be necessary to drill a hole with a drill with a diameter of 12 mm.

The main stages of work

After we have drilled a hole in the pipe, we weld a nut under the M12 stud. Opposite the nut on the opposite side, drill a hole with a diameter of 2.5 mm. A drill with a diameter of 8 mm needs to be made a small poty.

Using an angle grinder, we make a cut in the place where a small hole was drilled. Then, between the two holes, approximately in the middle of the pipe, it will be necessary to weld the M8 bolt.

We wind the handle from the drill or perforator onto the stud of the welded bolt. At the last stage, we make a selection in the slot, after which we fasten the previously prepared part from an ordinary stud and bolt.

In this case, there is a chance that the rivet leg breaks ahead of time, but poor-quality rivets break even with a factory rivet. For a step-by-step process of manufacturing a homemade rivet for blind rivets, see the video on the site.