This tool in the household (in a private house or in the country) will definitely not be superfluous, especially at the height of the heating season, because it is designed for comfortable cutting of large logs. Using a homemade metal stand is much more convenient than sawing on the ground in an "awkward" position.

As the main material for the manufacture of the rack, a profile pipe of square section 40x40 mm is perfect. An angle of 50x50 mm and bolts with M12 nuts will also be required. All components are available for sale and are inexpensive.

The first thing we cut off from the profile pipe is two pieces 50 cm long at an angle of about 40 degrees. Also for this homemade product a profile of 50x50 mm and a metal strip 4 cm wide are required. From the profile we cut a piece of 40 cm at an angle of 90 degrees.

The main stages of work

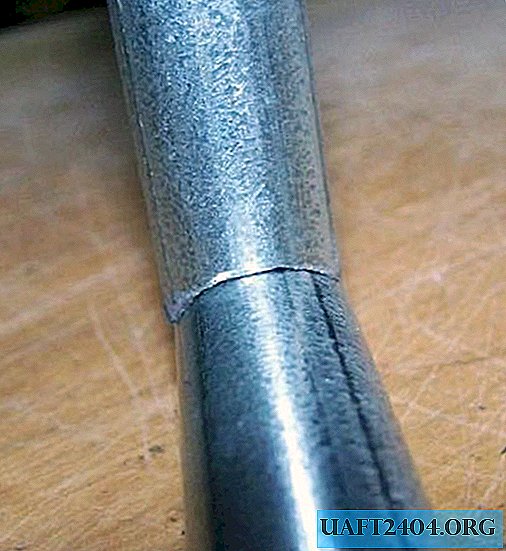

As planned, the profile pipe 40x40 mm should be inserted into the profile 50x50 mm. Moreover, to remove the backlash, it is necessary to insert two segments of the fortieth strip into the 50th profile, and scald them. Thus, the gap will become smaller and there will be practically no backlash.

To grab the strips in the middle, a through hole must first be drilled in the profile pipe. At the next stage, cut a length of 80 cm from the 40x40 mm profile. Next, mark and drill holes for adjusting the device in height.

Then it remains only to weld the lower part of the structure (stand and persistent legs), as well as a fastener for quick fixation of the log. For details on how to make a metal stand, see the video on the site.