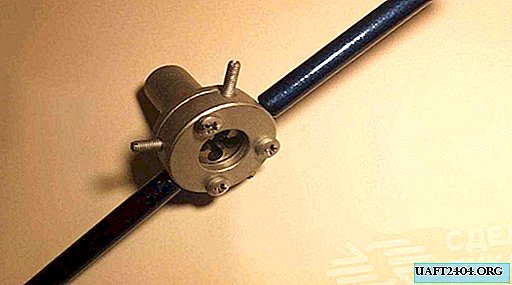

Using a simple die holder with a guide welded to it, which you can make with your own hands, cutting even threads on the workpiece (steel bar, pipe, bolt, etc.) will not be difficult.

Please note that in this case there is no need to make a die holder from scratch - it is quite possible to use the factory one. It will be necessary to make only the guide sleeve itself (for the diameter of the workpiece).

First of all, it is necessary to cut a washer from a piece of plate 12-14 mm thick that is suitable in size to the "holder" of the ram holder. Then you need to drill holes in the die holder, and cut the threads into them.

The main stages of work

Next, you need to make the guide sleeve itself. For this, the master takes a piece of steel pipe of suitable diameter. In this pipe (at the edges) it is necessary to press in the nuts. Previously, the external faces must be grinded.

A piece of pipe is first put on a bolt suitable for the thread of nuts, and then the master presses the nuts themselves into it.

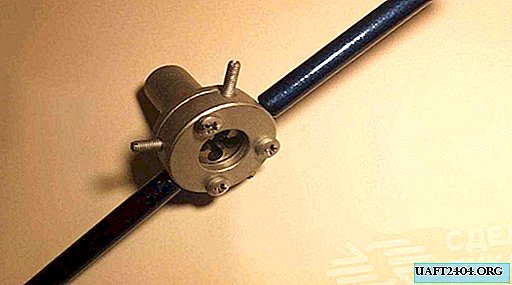

At the last stage of work, it will be necessary to weld the guide sleeve to a previously made metal washer. Then the device is screwed to the factory die holder. And now the homemade product is completely ready.

In detail about how to make a guide to the die holder with your own hands, we recommend that you look in the video on the site.