From the angle grinder, which can be removed from the old grinder, you get a simple grinding nozzle on a drilling machine. You can attach a table to a homemade nozzle to make it easier to process workpieces.

Of course, if there is an ordinary grinding machine or grinder, then there is no need for such a nozzle. However, in the absence of a grinding device and in the presence of a drilling machine, you can well get by with such a nozzle (for various small jobs).

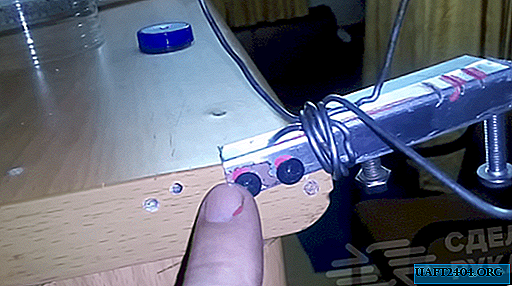

The first step is to disassemble the grinder and remove the gearbox. The motor shaft must be cut off, leaving a small “shank” so that the gearbox can be fixed in the drill chuck.

The main stages of work

The next step is to cut a circle from a piece of chipboard 18 mm thick. This can be done using a ballerina drill. Next, four holes must be drilled in the workpiece so that the clamping nut for the grinder can be fixed.

After that, the diameter of the circle from the chipboard will need to cut sandpaper and stick it to the surface of the circle on superglue.

At the last stage, it remains only to screw a pair of metal corners (bracket) to the gear case. These brackets are screwed to a piece of chipboard, from which previously a circle for sandpaper was cut out.

For more information on how to make a grinding nozzle for a drilling machine from a angle grinder with your own hands, see the video on the website.