An electric drill, like a grinder, is often used as a drive for various devices and devices. For example, on the basis of a network electric drill, you can make a desktop lathe. Read more here.

And using a simple homemade nozzle, you can even sharpen drills with a drill. This is very convenient when there is no electric sharpener at hand.

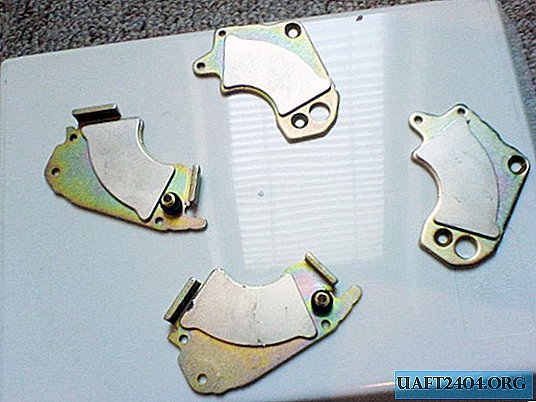

A homemade nozzle consists of a plastic case (in this case, the author uses pieces of plastic pipe and the transition from a smaller diameter to a large one).

A special nozzle for a drill for sharpening drills rotates inside the case. The drills themselves are inserted into the holes in the wooden workpiece, drilled at the right angle.

The main stages of work

First of all, in the electric drill chuck, you need to fix the nozzle for sharpening the drills. Then the author puts on a piece of plastic pipe on the “neck” of the case and fixes it with a metal clamp.

Another piece of a larger diameter is put on this pipe section, and a plastic transition is inserted into it. At this stage, you do not need to connect the blanks to each other.

In a small plaque, the master drills four holes at an angle of 118 degrees. Each hole is for a specific drill diameter.

Then with the help of a circular saw it is necessary to cut a circle from the board. It will need to be pressed into a large hole in the plastic junction.

At the last stage, all the elements of the body must be glued together. Or you can make a collapsible design - this is at your discretion.

For details on how to make a nozzle for an electric drill for sharpening drills, see the video on our website.