Chopper in the country - one of the most popular tools. Here are just those choppers that are sold on the market, far from always turn out to be of high quality, and break very quickly. A good chopper can be made from a piece of a band saw for a sawmill.

Actually, the process of making a chopper itself is very simple, there’s no need to even explain anything. In this review, we’ll talk about some of the nuances that may be of interest to someone.

Necessary materials and tools:

- a piece of the band saw blade for the sawmill;

- piece of steel half-inch pipe;

- a piece of round bar with a diameter of 16 mm;

- angle grinder (grinder);

- welding machine;

- sledgehammer and construction dowel-nail.

Features of the manufacture of choppers

If you can cut blanks for chopping from a piece of saw blade without any problems, then drilling holes in them is very difficult, the drills “burn”. Web thickness - 2.8 mm.

Therefore, the author had to punch holes in the blanks using a building dowel-nail. It makes its way, though for a long time, but still makes its way.

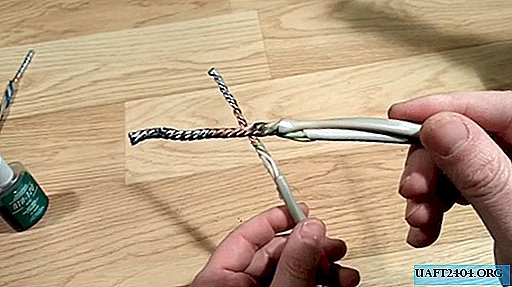

To fix the holder, the author uses a piece of a half-inch steel pipe. Cut it to size (desired length), drill a hole, and then cut it into a cone. To fix the chopper, the author made a hook from a round bar with a diameter of 16 mm.

We prepare all the necessary parts and weld them together. Then we clean the welds with a grinder. The result is a very durable chopper that will last a long time.

For details on how to make a chopper from a piece of a band saw for a sawmill, you can see in the video on our website.